1) NOS drive sprocket

puller 66-74 - #12 on the figure below) - price $65 weight

of this tool set is 2 lbs

1) NOS drive sprocket

puller 66-74 - #12 on the figure below) - price $65 weight

of this tool set is 2 lbs

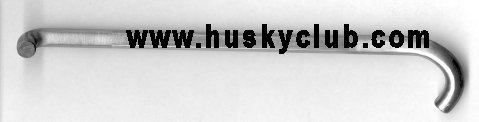

This

tool was included in all tool kits provided by the factory with all new

Husky bikes. weight is 0.5 lbs. price - $20

This

tool was included in all tool kits provided by the factory with all new

Husky bikes. weight is 0.5 lbs. price - $201) On any puller type tool using a threaded shaft or large threads to do the work YOU MUST HAVE THE THREADED WORK PORTION WELL GREASED. This would apply to items above #2 magneto puller , #6 clutch hub puller, #11 case splitter, #9 small brg puller, #14 case assembler. We all like to keep neat tidy tools in our storage. Do not make the mistake of using a small amount of grease to lube this style tool for fear of getting your storage dirty. Maybe store in a plastic bag. You will get much better performance out of a well lubricated tool and the tool will last much longer.

2) After cleaning your zinc plated tools in a solvent, you must coat them with something to avoid corrosion. WD40 will work fine. DO NOT USE this corrosion protection coating as your thread lubricant for above.

3) Study and understand how each tool works. This may sound rather basic, sorry. Make sure that the thread engagement into engine parts is smooth and many full threads. If there are other moving or sliding fits on the tool , make sure the tool is well lubed to allow all the fits to find least strain and allow all work energy to go to the tool task. A magneto puller must be threaded into the magneto until it bottoms, this is 4 to 6 complete threads. 6mm screws holding case splitter must be 4 to 6 threads in as well. The clutch hub puller only needs 2-3 threads on the 6mm attaching screws as the material of the hub is rather thin.

4) Do not overtorque a puller tool to the point of breaking and then figure out what would have been a better technique. Have a maximum torque in mind for a puller, then enlist heat or shock to break a tight fit if needed.

5) All of these type tools are intended for maintaining a nice, cared for motorcycle. Using any tools to take apart a rusty junk yard bike, a negleted hacked up basket case, or e-bay special will probably ruin all your tools unless you use experience and good judgment in the process.